Hot Dip Galvanized Steel Pipe

Key Words:

Subclassification:

Galvanized steel pipe

Email:

WhatsAPP:

| Product name | galvanized steel pipe | |||

| Pipe end | plain end | |||

| Pipe Length | 3 meters-12 meters | |||

| Outside daimeter | 1/2 inch~8 inch | |||

| Pipe fittings | threaded, coupling, caps, flange, etc | |||

| Materials | Q195, Q235, Q235B, St37-2, St52, SS400, STK500, ASTM A53, S235JR | |||

| Standard | GB/T3091, ASTM A53, JIS G 3444, BS 1387 | |||

| Surface | galvanized | |||

| Zinc Coating | more than 60g/m2-600g/m2 | |||

| Payment term | T/T, L/C, Western Union, Cash, etc | |||

| Applications | water pipe, low fluid transportation, scaffolding pipe, greenhouse pipes | |||

| Certificate | ISO9001, SGS, TUV, BV | |||

Types of galvanizing process for plumbing pipes:

There are many different types of galvanizing processes depending on the desired outcome or properties of the finished product.

The most popular methods include hot-dip galvanizing, electroplating, mechanical electroplating, and plastic coating.

Hot-dip galvanizing is currently considered one of the best methods of galvanizing steel pipe due to its durability and corrosion resistance.

The method involves immersing the metal in a bath of molten zinc at 450 degrees Fahrenheit.

The process is complete when the steel pipe (or EN (European Standard) or ASTM (American Society for Testing and Materials))

standard material is coated with approximately 30 to 40 microns of pure zinc.

Electroplating is another popular method of galvanizing steel pipes because of its high-quality finish and relatively inexpensive cost

compared to other methods such as hot-dip galvanizing.

Electroplating uses an electric current to deposit a thin layer of chromium, nickel or zinc on an existing metal surface.

Mechanical plating, also known as mechanical polishing, is a low-cost alternative that involves adding a thin layer of zinc using a sandblasting (shot peening) method.

This type of galvanizing process is less popular due to its lower surface quality and its tendency to flake or peel.

Plastic coatingis the least used method of galvanized steel pipe due to its limited functionality and poor corrosion resistance.

Hot-Dip Galvanized Steel Pipe, a robust and reliable material, plays a pivotal role in modern construction and engineering projects. This type of steel pipe undergoes a rigorous process where it is coated with a thick layer of zinc through hot-dipping, providing exceptional corrosion resistance and longevity. The zinc coating acts as a sacrificial barrier, protecting the underlying steel from rust and environmental degradation, even in harsh conditions.

The manufacturing process involves several meticulous steps to ensure the highest quality. Initially, the steel pipe is thoroughly cleaned and prepared to remove any surface impurities. It is then immersed in a bath of molten zinc at temperatures exceeding 450°C (842°F). This high-temperature zinc coating creates a metallurgical bond with the steel, resulting in a uniform and durable finish that can withstand the test of time. The thickness of the zinc coating is carefully controlled to meet international standards, typically ranging from 40 to 200 microns, depending on the specific application and required level of protection.

One of the key advantages of Hot-Dip Galvanized Steel Pipe is its outstanding durability in outdoor environments. Whether used in building structures, transmission towers, or utility poles, this pipe excels in resisting weather elements such as rain, snow, and UV radiation. Its ability to maintain structural integrity over extended periods makes it a cost-effective solution for infrastructure projects. Additionally, the non-toxic nature of the zinc coating ensures safety for both workers during installation and end-users throughout the lifecycle of the structure.

Factory

Hebei Yehui Metal Materials Co., Ltd. was established in 2015, located in Shandong Province, with a 20000 square meter factory. We have passed the "ISO9001 quality system certification, EU CE certification".

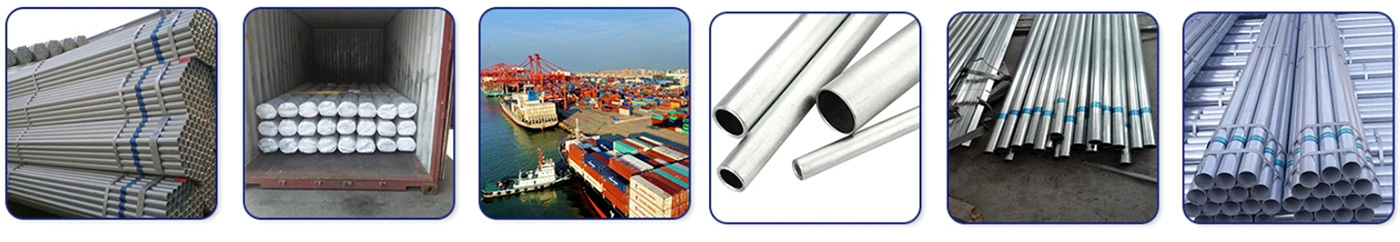

Packing And Delivery

We adhere to the management principle of "quality first, service first, continuous improvement and innovation, and customer satisfaction", with the quality goal of "zero defects, zero complaints". We are pleased to receive your inquiry and will reply as soon as possible.

Application

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

Related Products

FAQ

Message