Seamless Steel Pipe Seamless Alloy Steel Tube

Key Words:

Subclassification:

Seamless Pipe

Email:

WhatsAPP:

Product introduction

This specification covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. The pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their micro-structure. Tensile tests, impact tests, hydro-static tests, and nondestructive electric tests shall be made in accordance to specified requirements.

1.This specification covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Several grades of ferric steel are included as listed in Table 1. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on low-temperature impact properties.

2. Supplementary Requirement S1 of an optional nature is provided. This shall apply only when specified by the purchaser.

3. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

Technical data

Seamless Steel Pipe Chemical Composition and Mechanical Properties

This data is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

| Standard | Grade | Chemical Composition (%) | Mechanical Properties | ||||||

| ASTM A53 | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | ||

| A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | ||

| B | ≤0.30 | - | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 | |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | ||

| ASTM A179 | A179 | 0.06-0.18 | - | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | |

| API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | ≥331 | ≥207 | |

| B | 0.28 | - | 1.20 | 0.030 | 0.030 | ≥414 | ≥241 | ||

| X42 | 0.28 | - | 1.30 | 0.030 | 0.030 | ≥414 | ≥290 | ||

| X46 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥434 | ≥317 | ||

| X52 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥455 | ≥359 | ||

| X56 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥490 | ≥386 | ||

| X60 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥517 | ≥448 | ||

| X65 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥531 | ≥448 | ||

| X70 | 0.28 | - | 1.40 | 0.030 | 0.030 | ≥565 | ≥483 | ||

| API 5L PSL2 | B | 0.24 | - | 1.20 | 0.025 | 0.015 | ≥414 | ≥241 | |

| X42 | 0.24 | - | 1.30 | 0.025 | 0.015 | ≥414 | ≥290 | ||

| X46 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥434 | ≥317 | ||

| X52 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥455 | ≥359 | ||

| X56 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥490 | ≥386 | ||

| X60 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥517 | ≥414 | ||

| X65 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥531 | ≥448 | ||

| X70 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥565 | ≥483 | ||

| X80 | 0.24 | - | 1.40 | 0.025 | 0.015 | ≥621 | ≥552 | ||

Carbon Steel Seamless Pipe Chemical Composition and Mechanical Properties :

| Standard | Grade | Chemical Composition | Mechanical Properties | |||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | ||

| GB/T8163 | 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.25 | ≤0.25 | 335-457 | ≥205 | ≥24 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 | 410-550 | ≥245 | ≥20 | |

| Q345 | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | ≤0.045 | ≤0.045 | - | - | - | 490-665 | ≥325 | ≥21 | |

Carbon Steel Seamless Pipe Tolerance :

| Pipe types | Pipe Szie(mm) | Tolerances | |

| Hot rolled | OD | All | ±1% (min ±0.50mm) |

| WT | All | +15%, -12.5% | |

| Cold drawn | OD | 6~10 | ±0.20mm |

| 10~30 | ±0.40mm | ||

| 30~50 | ±0.45mm | ||

| >50 | ±1% | ||

| WT | ≤1 | ±0.15mm | |

| >1~3 | +15% -10% | ||

| >3 | +12.5% -10% | ||

Seamless Steel Pipe End :

| Plain End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Plain End (Square Cut) | Wall Thickness over 0.5 inch, including SCH XXS |

| Beveled End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Couplings | Outside Diameter equal or less than 2'' |

| Thread Protection | Outside Diameter over 4 inch |

Products Display

Seamless Alloy Steel Tube, a high-performance tubing solution, is meticulously designed for diverse industrial applications. Its outstanding corrosion resistance stems from the addition of alloying elements such as chromium and molybdenum, which effectively safeguard against rust and chemical erosion. With excellent mechanical properties, it maintains structural integrity under high pressure and temperature fluctuations, ensuring reliable performance in extreme conditions.

The tube's seamless construction eliminates weak points found in welded seams, enhancing its overall strength and durability. This feature makes it ideal for critical applications like oil and gas exploration, where pipeline integrity is paramount. Moreover, Seamless Alloy Steel Tube boasts superior heat resistance, enabling it to withstand intense thermal stress without compromising its physical characteristics.

Its versatility extends to various industries, including automotive, aerospace, and petrochemical, due to its ability to be customized in terms of size, thickness, and alloy composition. The precise dimensions and smooth finish facilitate easy installation and integration into complex systems, reducing downtime and maintenance costs. Additionally, the material's compatibility with different forming processes allows for the fabrication of intricate shapes and components, further broadening its application scope.

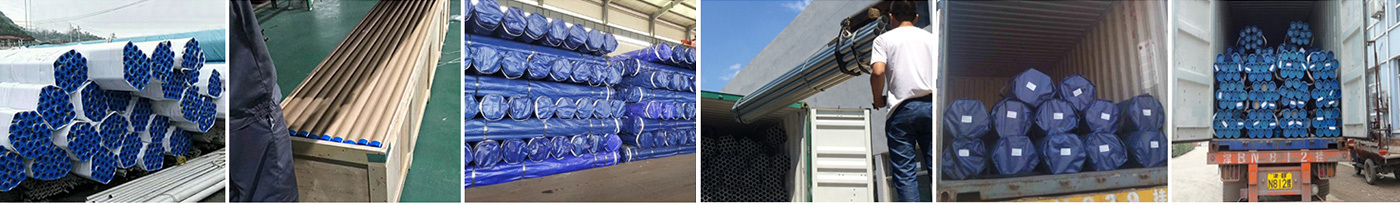

Warehouse Storage

With 13 years of experience in competitive steel products at home and abroad, to provide reliable services to global customers.The main products are steel pipe, steel plate, steel coil, steel rod, steel strip, section steel, silicon steel, stainless steel series, carbon steel series, aluminum products and so on. Products are widely used in precision instruments, aviation, ships, automobiles, home appliances, construction, bridges, boilers, highway guardrail and other industries.

Packing and shipping

Products are widely used in precision instruments, aviation, ships, automobiles, home appliances, construction, Bridges, boilers, highway guardrail and other industries. Annual sales of more than 6 million tons. Products are exported to more than 80 countries and regions. We have won the recognition of customers with good reputation and good service.

Application field

Our main products are steel pipe, steel plate, steel coil, steel strip, section steel, silicon steel, stainless steel series, carbon steel, galvanized color coating series, etc. Products are widely used in precision instruments, aviation, ships, automobiles, medical, construction, Bridges, boilers, parts processing and other industries.

Related Products

FAQ

Message